Pour bénéficier d’un affichage optimal de la boutique en ligne de PanGas, vous avez besoin pour le navigateur de la version minimale suivante:

• Internet Explorer 9.0

• Mozilla Firefox 38

• Safari 8

• Chrome 45

Veuillez vous assurer que JavaScript est activé dans les paramètres de votre navigateur.

- Accueil

- Applications

- Analyse & Instrumentation

- High-Performance Liquid Chromatography

High-Performance Liquid Chromatography (HPLC)

High Performance Liquid Chromatography (HPLC) is a form of column chromatography that pumps a sample mixture or analyte in a solvent (known as the mobile phase) at high pressure through a column with chromatographic packing material (stationary phase). HPLC has the ability to separate, and identify compounds that are present in any sample that can be dissolved in a liquid in trace concentrations as low as parts per trillion. Because of this versatility, HPLC is used in a variety of industrial and scientific applications, such as pharmaceutical, environmental, forensics, and chemicals.

Sample retention time will vary depending on the interaction between the stationary phase, the molecules being analyzed, and the solvent, or solvents used. As the sample passes through the column it interacts between the two phases at different rate, primarily due to different polarities in the analytes. Analytes that have the least amount of interaction with the stationary phase or the most amount of interaction with the mobile phase will exit the column faster.

Instrumentation:

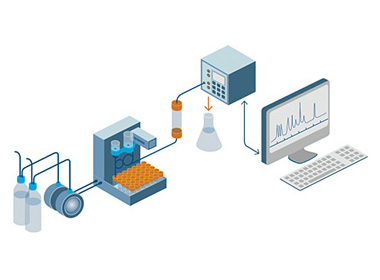

Main components in an HPLC system include the solvent reservoir, or multiple reservoirs, a high-pressure pump, a column, injector system and the detector.

The reservoir holds the solvent, which is referred to as the mobile phase because it moves. There are usually a minimum of two reservoirs in a system, with each holding up to 1000 cc of solvent and usually fitted with a gas diffuser through which helium can be bubbled. A pump is used to generate a specified flow of the mobile phase. Although manual injection of samples is still possible, most HPLCs are now fully automated and controlled by computer. The injector, or auto sampler, introduces the solvent into a phase stream that carries the sample into the high pressure (up to 400 bar) column, which contains specific packing material needed to effect separation. The packing material is referred to as the stationary phase because it is held in place by the column hardware.

A detector is needed to see the separated compound bands as they elute from the high pressure column. The information is sent from the detector to a computer which generates the chromatogram. The mobile phase exits the detector and is either sent to a waste, or collected, as desired.

With HPLC, a high purity helium is to degasse the mobile phase. Helium as well as Nitrogen is also used as a Nebulization gas.

High-Performance Liquid Chromatography - Other HPLC Types

- Ultra High Performance Liquid Chromatography (uHPLC):

Where standard HPLC typically uses column particles with sizes from 3 to 5µm and pressures of around 400 bar, uHPLC use specially designed columns with particles down to 1.7µm in size, at pressures in excess of 1000 bar. The main advantage of an uHPLC is speed. These systems are faster, more sensitive, and rely on smaller volumes of organic solvents than standard HPLC, resulting in the ability to run more samples in less time. However, if the systems are run at typical pressures greater than 800 bar, the columns age, or degrade quicker. Newer technology is being developed for uHPLC units to use column particles with 1µm size, and pressure potentials up to 6,800 bar.

uHPLC is also known as UPLCTM, a trademark of the Waters Corporation. - Fast protein liquid chromatography (FPLC):

FPLC is a system similar to high-performance liquid chromatography that is used to separate or purify proteins and other biomolecules from complex mixtures. The main difference between FPLC and HPLC is the standard working pressure. FPLC columns can only be used up to maximal pressures of 3-5 MPa. If the pressure of the HPLC can be limited, nearly every FPLC column may also be used in an HPLC system.